Why Boston Matthews?

Customer service

that is second to none

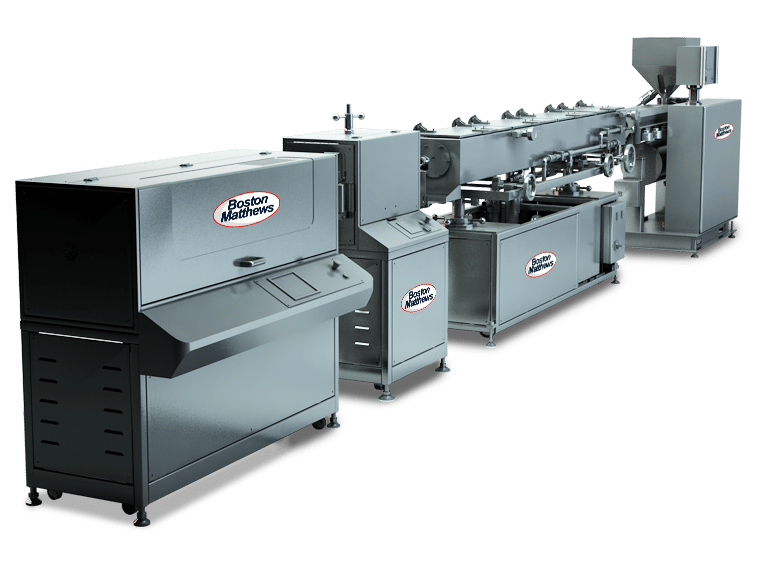

For more than 65 years Boston Matthews has been at the forefront of extrusion machinery technology.

As the Inventors of the Caterpillar Haul-Off Boston Matthews has earned a place in the coveted US Plastics Hall Of Fame and with over 10,000 direct descendants of the ‘Boston’ Haul-Off in daily use around the world is the leading manufacturer of Caterpillar Haul-Off.

Everything you need –

when you need it

With more than 35,000 machines installed around the globe, quality of service is guaranteed.

Ultimate solution / perfect production

across multiple sectors - at every stage of production

We’ve supported a global customer base for more than sixty years covering virtually every sector of manufacturing – and if you can’t see what you’re looking for here – just give us a call, we’re confident we can help solve your extrusion problems.

Boston Matthews is the original

inventor of the Caterpillar Take-Off

We’re proud to have invented the Caterpillar Take-Off and with many thousands of units in daily operation throughout the world the Boston (or Farris) is the No.1 Puller in the USA and The World.

Proud to have served the USA Plastics Industry since 1953.

Any problem? Just ask