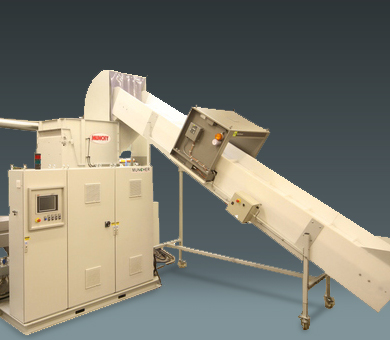

The highest quality output for Film Edge Trim & Roll Stock Recycling

Why Munchy ?

Our established, tried and tested solution offers minimal thermal degradation

Invest in your own business and give a second life to your old plastic waste with our Munchy machine.

From polyethylene and polypropylene to EPS and Nylon, this tried and tested solution ensures minimal thermal degradation.

Blown film & edge trim recycling benefits with Munchy

We work with the client at every step to solve even the most complex problems, ensuring your machine is right for the most complicated of jobs

Discover

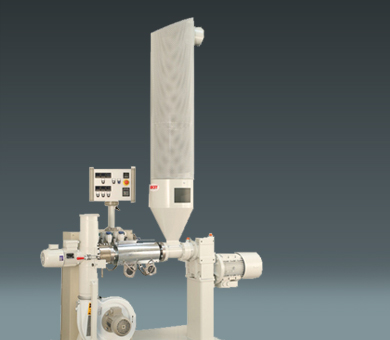

The Munchy family

Munchy understands that production environments and procedures differ from organisation to organisation. Therefore several different recycling methods are offered by Munchy.

Inventor of

The Dual Diameter Screw

Munchy are the inventors of the Dual Diameter Screw and was one of the first manufacturers of plastic recycling machinery.

Any problem? Just ask