Reasons to Recycle Your Scrap Plastics

In a perfect world there would be zero scrap from your production facility. However, even the most efficient operation produces a percentage of scrap material.

And this material has a real value to your business.

Why throw cash in the trash?

The cost of Resin is a large overhead to any plastics business. This coupled with rising energy and other production costs have made the need to make savings more important than ever.

The pellet produced using a MUNCHY System is of the highest possible quality = higher % back into production = higher cost savings.

Take the MUNCHY Challenge to see how much you could be saving.

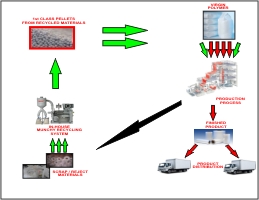

The Recycling Process

Solve Storage Problems

1st Class Pellets = Greater Savings

Landfill no longer an option

Take the MUNCHY Challenge to see how much you could be saving.

Direct Feeding Onto The Munchy Screw

Turning scrap plastics into re-useable 1st class pellets

Closed Loop Systems

Eliminated Cross Contamination

Got a question?

Just ask