PS Pipette Extrusion Lines

Boston Matthews is pleased to announce the introduction of a new extrusion line designed specifically for the production of Styrene (PS) Pipette Tubes.

Designed in co-operation with medical device manufacturers the Pipette Tube Line provides a completely versatile line capable of extruding, sizing, drying and accurately cutting the PS tubes without marking or swarf.

Designed for energy efficient operation and clean room conditions

Incorporated throughout the entire line are those elements that are required to meet with the production demands of today manufacturers including the strict regulations needed to manufacturer for the medical sector.

Direct-drive on the extruder not only ensures a clean, brushless operation but also provides maximum transmission of power which greatly assists energy efficiency. This is further enhanced with the use of AC Vector motor technology.

Maintenance is also greatly reduced using this technology and so reduces the risk of downtime and disruption to production.

All surfaces are easy to wipe down and the open plan construction allows for easy access for cleaning to all areas.

All surfaces that are in contact with water are made from high grade stainless steel to prevent any corrosion and risk of contamination.

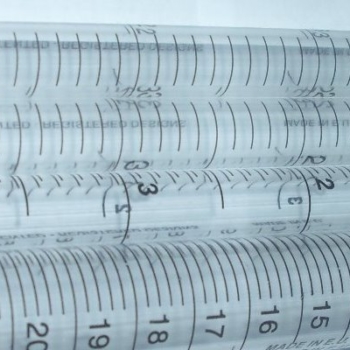

Capable of producing a range of tube sizes

The PS Pipette Line from Boston Matthews allows for a range of pipette tube sizes to be manufactured. Easy to change tooling and settings reduce the time taken to change from one tube size/specification to another in a relatively short space of time. The ability to change tube sizes allows the manufacturer to meet with the changing demands of their customers without incurring massive disruption to production or requiring investment in several separate items of production equipment. Typical tube sizes range from 1 ml capacity tubes to 25 ml capacity. All tubes are manufactured and cut to length in-line with an output at up to 30 tubes per minute. This output can equate to 60 formed pipettes per minute for some sizes.

New development provides swarfless, accurate Pipette Tube cutting

Designed using 3D Parametric Computer Design Software the PS Tube Cutter represents a significant advancement in tube cutting. The ability to automatically synchronise to the line speed enables tubes to be cut accurately and consistently to close tolerances without marking, shattering, or producing any swarf. The swaffless cutting technology not only provides a cleaner production environment but greatly reduces operational costs through a significant reduction in scrap material levels.

Boston Matthews Sales Director Simon Brookes states ""Styrene is an extremely tricky material to cut without causing shattering or damage. It is essential that the tubes are accurately cut to tolerance without any imperfections or swarf as the tubes are subjected to several completely automated post-extrusion processes.

This represents a significant development in the cutting of PS Tubes and provides Pipette manufacturers with an effective solution to what has been a major production issue for a long time. Our development in cutting technology has

allowed us to achieve this and ultimately increase the production capacity of pipette manufacturers.”

Complete Line Control and Product Traceability

Complete PLC control through the SMART system is also available with the PS Pipette Tube Line. The SMART colour touch-screen control system allows for simple line operation and quick start-up as well as providing essential tools for the tube manufacturer’s management. Password protection ensures line settings and production security is always controlled and maintained. Production data is fully accessible and transferable through a variety of means including Ethernet and modem. This allows for production data to be used for product quality analysis, traceability and efficiency reports. Simon Brookes states ""The Smart control system provides the manufacturer with the means to control the extrusion operation as well as the ability to access a large amount of data if required.”

Boston Matthews has designed and manufactured extruders, downstream equipment and complete extrusion lines for more than 50 years and are the inventors of the Caterpillar Haul-Off. Boston Matthews has over 35,000 machines in daily operation in more than 70 countries worldwide with manufacturing facilities located in Worcester, England. This is further supported by facilities in the USA and China.